“Fire Resistance in Plastics" addresses the need for flame retardants for e-mobility – halogen-free solutions in clear focus

The Fire Resistance in Plastics is one of the most prominent examples in Europe for the fire-retardant industry, to learn more about new developments, trends and market needs and especially a perfect opportunity to network with key professionals from this industry.

The 16th edition of this event took place on 30th November - 2nd December 2021 at the Radisson Blu Scandinavia Hotel, Düsseldorf, Germany. Despite the ongoing pandemic and the associated obstacles and challenges for live meetings, the event took place on site and in-person.

In the context of ever evolving technologies and new requirements, one session dealt with new fire challenges of Green Energy in Buildings. This session merged with the European Fire Safety Week that took place in parallel, which underlines the importance and relevance of this topic. After the opening by Adrian Beard, Clariant and Chairman (Europe) of pinfa, several presentations dealt with fire risks of photovoltaic systems and stationary batteries, which are important for the necessary energy transition in Europe.

In general, the topic of flame protection is of crucial importance as soon as currents flow. In addition to photovoltaics, the currently very prominent topic of batteries and especially e-mobility and new energy vehicles should be mentioned here.

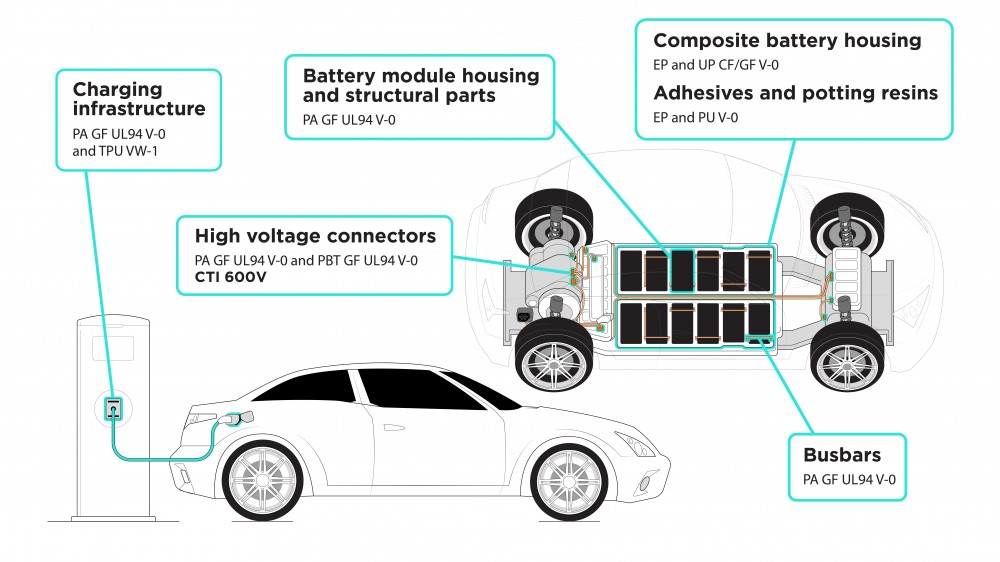

In the presentation of Marc Leifer, ICL, Israel, and Kasturirangan Kannah, Chairman of BSEF, UK, also the megatrend of e-mobility was highlighted with special focus on brominated flame retardants.

The general background to the widespread interest in e-mobility is that it has received a significant boost in recent times. The market has shown massive interest in halogen-free solutions in particular. Even if many compounds containing halogens are on the market, these seem to play only a subordinate role in mainstream research. For example, at Europe's most important scientific conference on flame retardancy this year, FRPM21, the clear focus was on halogen-free flame retardants.

Halogen-free solutions based on aluminum diethyl-phosphinate in particular have proven to be an excellent solution for e-mobility. Their excellent fire performance, thermal stability of the neat flame retardant and mechanical properties of the resulting polymer-flame-retardant formulation at good moldability are worth mentioning here.

In a study with pinfa and some of its members on recycling of post-industry waste also the phosphinate based flame retardant Exolit OP 1400 from Clariant was tested. The investigations were carried out at Fraunhofer LBF, Darmstadt, Germany, see here and here. Due to the good results and high market demand, Clariant has decided to build a new plant in China for these products and it will facilitate the transition to new energy vehicles globally.

In the field of fire retardancy, it is fundamentally important to understand the underlying mechanisms in order to be able to tailor and optimize systems for specific polymers and applications. On this topic Prof. Serge Bourbigot, IUF / UMET, France reported, with special focus on recent developments related to intumescent systems. Besides to successful use of intumescent systems in extreme fire scenarios like a jet fire, such systems could be potential solutions for space applications. This is also why first tests were carried out under microgravity, to better understand the influence of this special setting on performance.

Furthermore Dr. Yann Bourgeois, HUBER – MARTINSWERK, Germany, shared investigations about the synergistic behavior of melamine poly(metal phosphate) and metal hydrates. Especially in combination with aluminum hydroxide it has shown a good synergistic performance. Potentially the overall FR loading in cable compounds can be reduced.

The subject of synergistic systems has been an important topic for many years. In addition to countless scientific literature, more and more synergistic flame retardant (FR) systems are being commercialized and new patents are being published on the subject. By optimizing their formulation for a polymer and application, they can produce better performance than the components alone when used properly, often at lower loadings. This trend is likely to continue successfully in this industry.

Also relevant to this topic, an entire session focused on the topic of nano-based FR and systems. This topic has also been the focus of science and development for some time now. Dr. Günter Beyer, FIRE AND POLYMER, Belgium presented on nanocomposites. He explained that compounding and processing of nanocomposites is relatively simple on existing compounding-extruders. Results highlighted here that cable compounds based on ATH and organoclays result in highly effective FR-systems for the cable industry.

In summary, it can be said that the current topics on the subject of flame retardancy were well elaborated and successfully highlighted. In addition, despite the current situation, there was a successful exchange in the value chain and the next live events of this kind are looked forward to with pleasure.